Predictive Maintenance Using Telematics and Sensor Data

Predictive maintenance combines telematics, onboard sensors, and analytics to anticipate vehicle faults before they become critical. By continuously monitoring parameters such as battery health, drivetrain vibrations, and software diagnostics, fleets and vehicle owners can prioritize repairs, reduce downtime, and extend component life. This approach supports electrification efforts and helps maintain safety and resale value through data-driven interventions.

What role does telematics play in predictive maintenance?

Telematics acts as the nervous system for modern vehicles, aggregating GPS, vehicle CAN-bus data, and remote diagnostics into a central platform. It captures maintenance signals like engine codes, mileage, fluid temperatures, and usage patterns. When combined with machine learning models, telematics trends—such as increasing fault-code frequency or irregular operation—can trigger predictive alerts. For fleets, telematics enables prioritization of service windows, route adjustments to reduce strain, and centralized reporting to track recurring failures across similar assets.

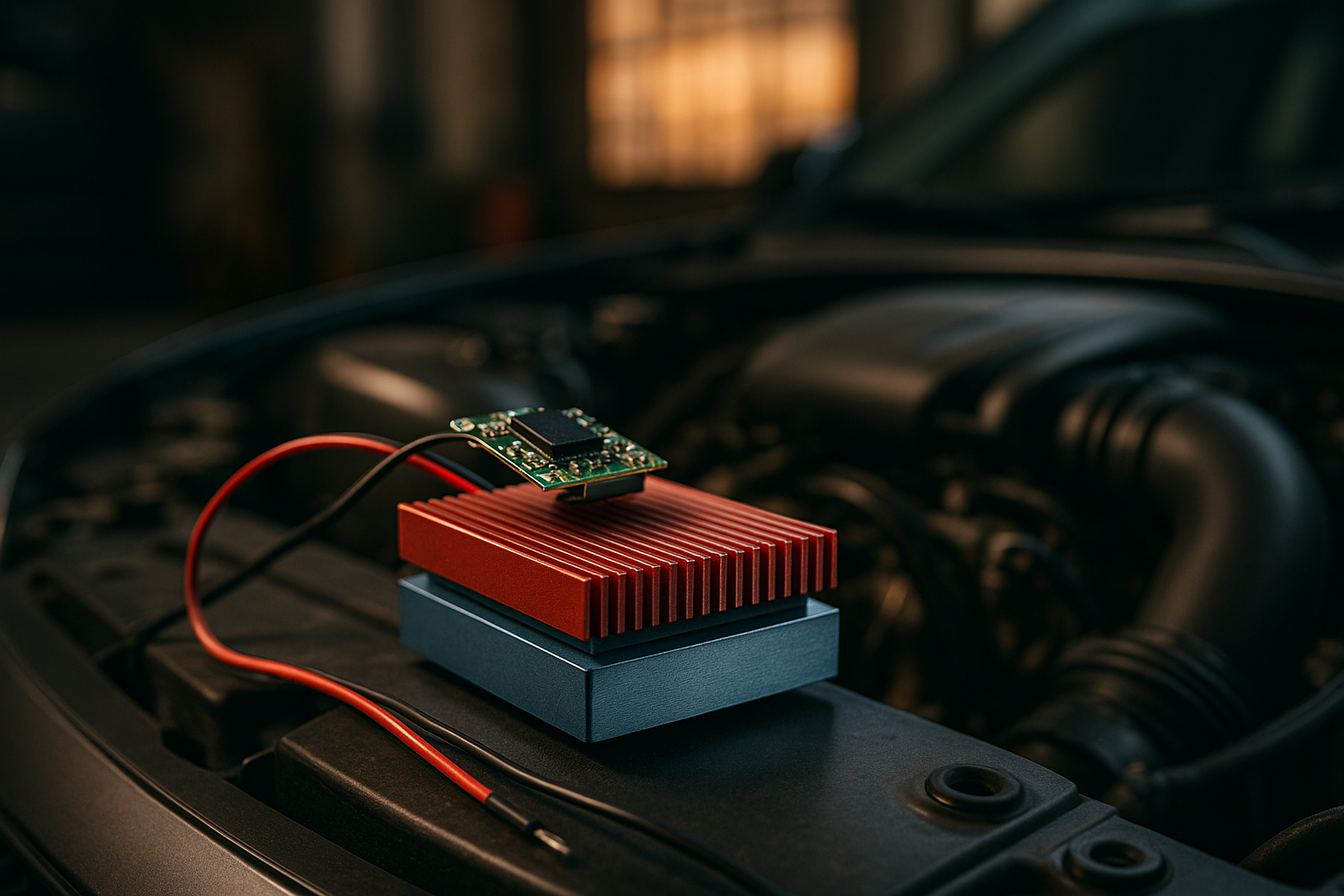

How do sensors and diagnostics predict battery issues?

Battery health prediction depends on continuous measurement of voltage, current, temperature, and impedance. Advanced diagnostics use time-series sensor data and charge/discharge cycle histories to estimate state of health (SoH) and remaining useful life (RUL). For electrified vehicles, detecting thermal anomalies, uneven cell degradation, or unusually high internal resistance early allows operators to schedule battery conditioning, recalibration, or module replacement before capacity loss or safety incidents escalate.

Can electrification and charging data improve longevity?

Charging behavior directly affects battery life; fast-charging frequency, state-of-charge windows, and ambient temperature during charging are all predictive factors. Telematics that capture charging sessions, power levels, and station type provide context for analytics models to recommend optimized charging practices. For fleet electrification, these insights inform charging infrastructure deployment, route planning to avoid high-stress charging patterns, and education for drivers to adopt charging habits that support sustainability and lower total cost of ownership.

How does cybersecurity affect retrofit and ADAS integration?

As vehicles incorporate ADAS, infotainment, and retrofit telematics modules, the attack surface expands. Predictive maintenance systems must ensure data integrity and secure OTA updates so diagnostics and sensor inputs are trustworthy. Cybersecurity measures—encryption, secure boot, certificate management, and intrusion detection—protect firmware in retrofit modules and ADAS controllers. Without robust security, false sensor data or compromised diagnostics could trigger incorrect maintenance actions or compromise safety-critical systems.

What is the impact on mobility, autonomy, and resale value?

Predictive maintenance supports broader mobility goals by keeping vehicles available and reliable, which is essential for shared mobility and autonomous fleets. Regular, data-backed maintenance histories can enhance resale value because prospective buyers and remarketers can verify usage, repairs, and component health through telematics records. For autonomy, consistent sensor calibration and proactive component replacement reduce the risk of perception or control failures, helping maintain safe operation and regulatory compliance over time.

How do infotainment and subscription models tie into maintenance?

Infotainment and subscription services generate additional telemetry—software versioning, app crashes, and user behavior—that can indirectly signal vehicle health issues. Subscription-based diagnostics or over-the-air feature subscriptions may include predictive maintenance modules as part of their offerings, enabling continuous updates to analytics algorithms. Integrating infotainment telemetry with vehicle diagnostics creates a fuller picture of operational context, while subscription models can finance ongoing analytics, support, and OTA remediation features that keep vehicles current.

Conclusion Predictive maintenance using telematics and sensor data is a multifaceted practice that improves reliability, reduces downtime, and supports electrification and sustainability objectives. By combining vehicle telemetry, battery diagnostics, cybersecurity practices, and user-context signals from infotainment and subscriptions, stakeholders can transition from reactive repairs to planned interventions. Over time, this approach contributes to safer vehicles, improved fleet economics, and clearer evidence of maintenance history for resale and regulatory purposes.